Why would you need conductive plastic?

Plastic – possibly the most common and most used material in our lives – is typically known for its universal applications – it is literally everywhere. But what if you could combine the lightweight, versatile nature of plastic with the ability to conduct electricity?

Let’s talk about conductive plastic, a game-changer across various industries. At ITO Plastic, we specialise in using Indium Tin Oxide (ITO) to create these innovative materials.

Why would you need conductive plastic?

Traditional plastics are used in so many different applications that it seems futile to list them here, we all know where and why plastic is used. But when you look at conductive plastic, further applications open up. Here we list some of the most common uses of conductive plastic.

- Electrostatic Discharge (ESD) Control: Imagine sensitive electronics getting fried by a simple touch. Conductive plastics help prevent this by dissipating static electricity buildup, protecting delicate components in devices like laptops and tablets.

- Electromagnetic Interference (EMI) Shielding: In today’s world of complex electronics, unwanted electromagnetic interference can disrupt device functionality. Conductive plastics act as shields, safeguarding sensitive components from external electromagnetic noise.

- Touchscreens and Transparent Displays: The ability to interact with our devices through touchscreens or see information displayed on clear surfaces has revolutionised technology. Conductive plastics play a crucial role in these applications by enabling transparent and responsive touchscreens and displays.

- Heating Elements: Yes, plastic can even conduct heat! Conductive plastics can be used in applications like heated seats or defroster grids, offering lightweight and flexible heating solutions.

ITO: The Secret Ingredient for Conductive Plastic Success

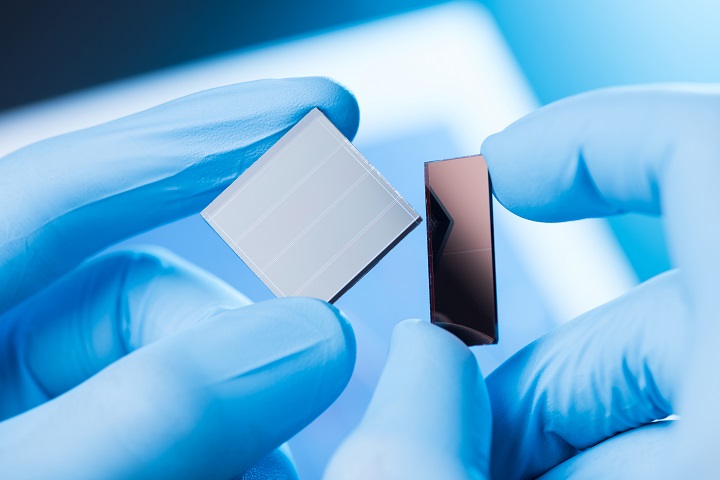

So, how do we transform regular plastic into a conductor? At ITO Plastic, we rely on the magic of Indium Tin Oxide (ITO). Here’s why ITO is the perfect partner for conductive plastics:

- Transparency and Conductivity Combined: ITO offers the unique ability to be both transparent and conductive. This makes it ideal for applications like touchscreens and displays where clarity is paramount while also requiring electrical flow.

- Tunable Conductivity: The level of conductivity in ITO plastics can be precisely controlled. This allows us to tailor the material to specific application needs, ensuring optimal performance.

- Durability: ITO coatings are known for their excellent scratch resistance, ensuring your conductive plastics maintain their functionality over time.

Where ITO Plastic Makes a Difference

ITO-based conductive plastics find applications in a vast array of industries:

- Consumer Electronics: From touchscreens in smartphones and tablets to EMI shielding in laptops, conductive plastics are a key component in modern consumer electronics.

- Automotive Industry: Conductive plastics are used in heated seats, defroster grids, and even touchscreens within car dashboards, enhancing comfort and functionality.

- Medical Devices: ITO plastics can be used in certain medical equipment to control ESD and ensure safe operation around sensitive medical instruments.

- Solar Energy: Transparent, conductive ITO coatings play a role in some solar cell designs, contributing to the efficiency of solar energy conversion.

ITO Plastic: Your Partner in Conductive Plastic Innovation

At ITO Plastic, we are passionate about pushing the boundaries of conductive plastic technology. We offer a variety of ITO-based conductive plastic solutions to meet your specific needs.

Ready to explore the possibilities of conductive plastics? Contact ITO Plastic today to discuss your project and discover how we can help you take your product to the next level.