Why would you need conductive plastic?

Conductive plastics are a thing! At first, you might wonder why a plastic would need to be conductive, but the versatile capabilities and transformative applications these materials bring to the table cannot be denied. Conductive plastics are often produced by the incorporation of Indium Tin Oxide (ITO).

Conductive plastic is being used across many industries, offering solutions that replace the limitations of traditional materials…

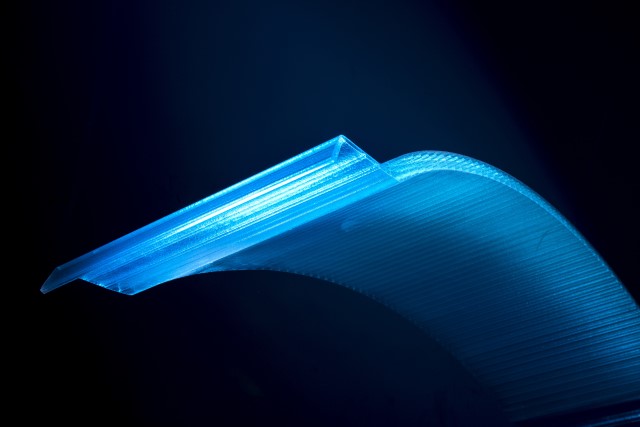

ITO Conductive Plastic

The unique marriage of ITO with plastic polymers enables the creation of lightweight, malleable components that retain electrical conductivity – a feat unattainable by standard plastics alone. ITO’s inherent conductivity lends itself to a multitude of applications across various sectors.

Within electronics, conductive plastics utilising ITO find their way into intricate circuits and housings of electronic devices, offering both structural support and electrical functionality. From intricate parts in smartphones and wearables to components in automotive sensors and medical devices, the presence of ITO enhanced conductive plastics is crucial in ensuring seamless functionality and durability.

Conductive plastics coated with Diamond Coatings ITO are also used for electromagnetic interference (EMI) shielding. These materials act as shields, mitigating unwanted electromagnetic interference that could disrupt the functionality of sensitive electronic equipment. Industries such as telecommunications, aerospace, and medical technology heavily rely on the shielding capabilities of conductive plastics utilising ITO to ensure uninterrupted operation of critical systems.

The evolution of smart packaging and flexible electronics owes a lot to the adaptability of conductive plastics enhanced by ITO. These materials, easily mouldable into various shapes and sizes while retaining electrical conductivity, pave the way for innovative packaging solutions and wearable technologies seamlessly integrating electronics into everyday objects.

The automotive industry embraces the benefits of conductive plastics incorporating ITO, utilising them in components for electric vehicles (EVs) and hybrid vehicles. These materials aid in the development of lightweight, conductive parts that contribute to the efficiency and performance of EVs, furthering the advancement of sustainable transportation.

The manufacturing process behind conductive plastics enhanced by ITO involves precise blending of ITO as a conductive coating with polymer matrices. This ensures the optimal balance between electrical conductivity and mechanical properties, resulting in materials meeting the stringent requirements of diverse applications.

The necessity for conductive plastics, particularly those leveraging ITO, stems from their unparalleled blend of electrical conductivity and the versatile properties of polymers. Their presence across industries underscores their indispensable role in driving innovation and shaping the future of technology and engineering.

If you have a specific requirement for conductive plastics, get in touch with us today. our team of tech experts are standing by, ready to work with you.