What Is ITO Plastic?

Let’s start with ITO… The abbreviated name for Indium Tin Oxide. ITO is an optically transparent substance that can be applied to substrates such as glass and plastic. Luckily, that’s not the end of it, ITO offers another benefit as well as being transparent – it is electrically conductive.

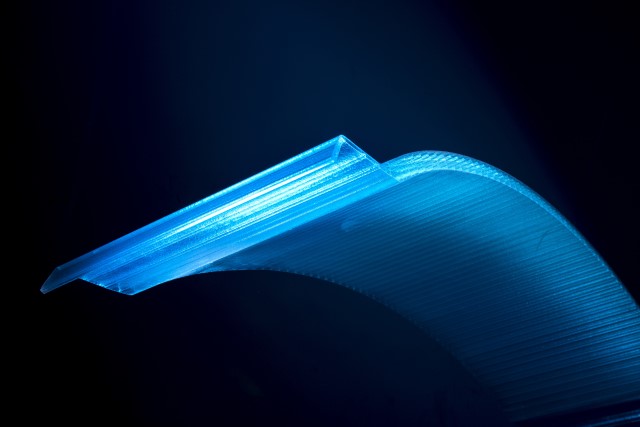

When plastic is coated in a thin film of ITO, it retains its original aesthetics, but also has the ability to carry an electric charge – that’s ITO plastic… (quite cool, right?)

Diamond Coatings ITO plastic

The Diamond Coatings range of ITO plastic substrates includes the following options:

- Polycarbonate (with or without Hard coat & Anti-glare coatings)

- Acrylic (with or without Hard coat & Anti-glare coatings)

- Polyester film

ITO coated plastic can be used in various applications where high optical transmission and conductivity is required.

Even though ITO coating on plastic can’t be soldered, it can be connected with the use of conductive inks, paints, copper tape with conductive adhesive etc. The polyester film has transmittance and resistance characteristics similar to glass substrates.

Why do you need ITO plastic?

You might be initially surprised, but the usage of ITO plastic is quite common, with applications ranging from EMI/RFI shielding and flexible printed circuits, resistive touch screens, medical sensors, membrane switches, electroluminescent lamps and optical clear heaters.

The most common of all would be the resistive touch screen. A resistive touch screen uses downward pressure to register a command and location of pressure on the screen, so are used in public facing and demand environments, such as ATM machines and supermarket self-serve kiosks, for instance.

Types of conductive plastic

Polycarbonates – Widely used within modern manufacturing, these substrates boast a range of interesting properties including optical properties and both impact and temperature resistance. Available with/without anti-reflective or hard-coat coatings, polycarbonates are a group of easily machined and coated thermoplastic polyesters.

Offering different polycarbonate grades with flame retardant and other properties, we can also supply these substrates with anti-reflective finishes suitable for a wide range of applications.

Acrylic – Also available with/without hard-coat/antireflective coatings, acrylic substrates are better optically although not as resilient as polycarbonates.

Further scratch resistant properties may be added together with anti-reflective coatings.

Resembling glass yet possibly superior to glass (the main advantage being weight, as acrylic is significantly lighter than glass), our acrylic substrates are hand-made and invariably inspected to exceptionally high optical specifications.

ITO Coated Films – In addition, we offer a range of ITO coated films on substrates including polyester, polyimide, polypropylene, and polycarbonate.

Diamond Coatings supplies ITO plastic to large numbers of original equipment manufacturers within electrical and electronic industries throughout Europe, the Far East and the USA.

Need more information?

If you have any questions regarding ITO plastic, or you have a specific query relating to your future project requirements, please get in touch with us today. A member of our technical team will respond as soon as possible.