The applications of advanced Plastic Coatings

Plastics have become so common place, offering versatility, durability, and cost-effectiveness across countless industries. However, to unlock the full potential of these materials and expand their applications, advanced plastic coatings have emerged as a game-changer. These specialised coatings transform ordinary plastics into high-performance materials with enhanced properties such as electrical conductivity, optical clarity, and resilience.

At ITO Plastic, we specialise in applying cutting-edge coatings to various plastic substrates, with a particular focus on Indium Tin Oxide (ITO). Let’s explore the remarkable ways these coatings are revolutionising the world of plastics.

Why Coat Plastics?

Plastic coatings address several key limitations of uncoated plastics:

- Protection: Coatings act as a shield, protecting plastics from scratches, abrasion, chemicals, UV radiation, and other environmental factors. This significantly extends the lifespan and durability of plastic components.

- Enhanced Properties: Coatings impart specific properties like electrical conductivity, anti-reflectivity, anti-fogging, or improved adhesion, enabling plastics to be used in applications where uncoated plastics would fall short.

- Aesthetics: Coatings enhance the visual appeal of plastics, offering vibrant colours, glossy finishes, or specialised textures that enhance product design and appeal.

The Rise of ITO Coatings on Plastic

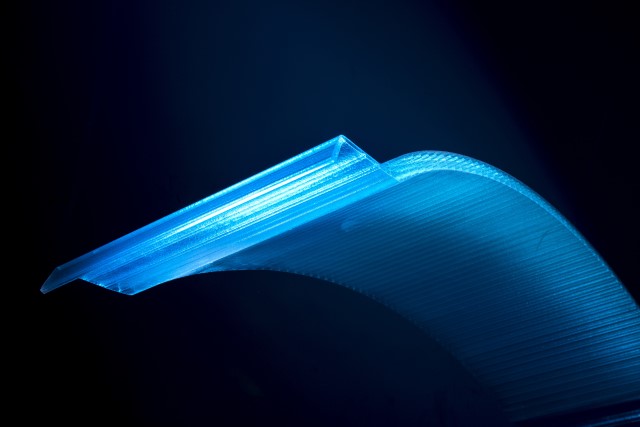

Indium Tin Oxide (ITO) is a transparent conductive oxide (TCO) renowned for its exceptional electrical conductivity and optical transparency. Applying ITO to plastic substrates has opened up a world of possibilities:

- Touchscreens: ITO-coated plastic films are the foundation of capacitive touchscreens found in smartphones, tablets, and various other electronic devices. The conductive ITO layer enables touch sensing, while the transparent plastic substrate maintains optical clarity.

- Flexible Displays: The flexible nature of plastic, combined with ITO’s conductivity, has paved the way for foldable and rollable displays, a revolutionary advancement in consumer electronics.

- Wearable Electronics: ITO-coated plastics are integrated into wearable devices like smartwatches and fitness trackers, where they enable touch interfaces and transparent displays.

- Solar Cells: In the renewable energy sector, flexible ITO-coated plastic substrates are used in thin-film solar cells, offering a lightweight and adaptable solution for harnessing solar energy.

- EMI/RFI Shielding: ITO coatings on plastic provide effective shielding against electromagnetic and radio frequency interference, protecting sensitive electronics in various applications.

- Anti-Static Applications: ITO-coated plastic helps dissipate static charge, preventing damage to electronic components in industries like manufacturing and healthcare.

Other Advanced Plastic Coatings

Beyond ITO, a wide range of coatings cater to specific needs:

- Anti-Reflective Coatings: Reduce glare and improve light transmission in applications like eyeglasses, camera lenses, and solar panels.

- Hard Coatings: Enhance scratch and abrasion resistance, making plastics suitable for demanding environments.

- Hydrophobic/Oleophobic Coatings: Repel water and oil, making surfaces easier to clean and maintain, ideal for touchscreens and displays.

- Anti-Microbial Coatings: Inhibit the growth of bacteria and other microbes, crucial for medical devices and hygiene-sensitive applications.

- Conductive Coatings (Non-ITO): Alternative conductive coatings, like carbon nanotubes or silver nanowires, offer unique properties and applications.

ITO Plastic: Your Partner in Advanced Coatings

At ITO Plastic, we specialise in applying ITO and other advanced coatings to a variety of plastic substrates, including PET, polycarbonate, and acrylic. Our expertise, state-of-the-art facilities, and commitment to quality ensure that your plastic components achieve the highest levels of performance, durability, and functionality.

Whether you’re developing cutting-edge electronics, creating innovative displays, or seeking to enhance the properties of your plastic products, we have the solutions you need. Contact us today to explore how advanced plastic coatings can take your products to the next level.