Plastic And Electricity – Can They Work Together?

Plastic: it’s lightweight, incredibly versatile, and found in nearly every product imaginable. Its widespread use stems from many properties, not least its excellent electrical insulation. This fundamental insulating property is why we wrap wires in it and rely on it for safety in countless electrical applications.

However, modern material science has begun to redefine what’s possible. The ability to make plastic electrically conductive, while maintaining its core advantages, is revolutionising product design. At ITO Plastic, we specialise in precisely this transformation, enabling a seamless integration of plastic’s versatility with electrical functionality through advanced coatings.

Transparent Conductive Oxides

So, if plastic is inherently an insulator, how can it work with electricity, not just block it? The solution lies not in altering the fundamental chemistry of the plastic itself, but in applying a microscopically thin, transparent layer that does conduct electricity. This is where Transparent Conductive Oxides (TCOs), particularly Indium Tin Oxide (ITO), enter the picture.

ITO is a unique material that manages to be both highly transparent (you can see right through it) and electrically conductive. This rare combination is the key to creating “smart plastics” that can interact with electricity.

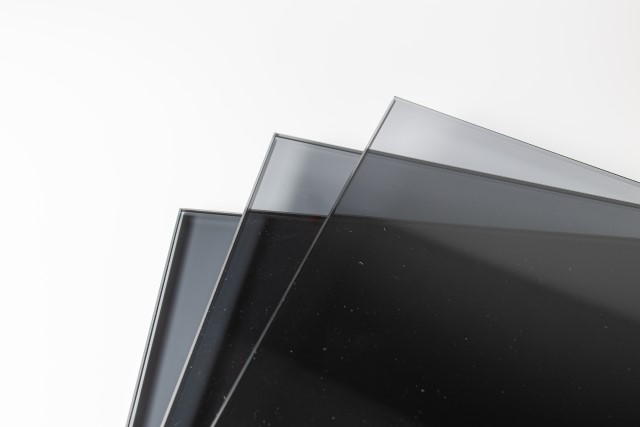

A Conductive Skin for Plastic

At ITO Plastic, we employ advanced vacuum deposition techniques to apply these ITO coatings to various plastic substrates. In a highly controlled environment, ITO material is vaporised and deposited onto the plastic surface. This forms an incredibly thin, uniform, and tightly adhered conductive film, often measured in mere nanometres.

Crucially, the electrical properties – how much resistance the film has – can be precisely controlled by adjusting the ITO coating’s thickness and composition. This allows for tailored solutions for various applications.

Why Electrically Conductive Plastic Matters

The ability to combine plastic’s inherent benefits with electrical conductivity opens up vast new design possibilities:

- Flexibility & Formability: Plastic can be bent, rolled, and moulded. When coated with flexible ITO, it retains these properties, enabling truly bendable electronic components and curved displays.

- Lightweight Solutions: Plastic is significantly lighter than traditional conductive materials like glass or metals, leading to more portable and energy-efficient products.

- Optical Clarity: The transparency of the ITO coating means that the conductive plastic remains clear, making it perfect for displays, sensors, and any application where light transmission is vital.

- EMI Shielding: The conductive layer can also act as an effective shield against electromagnetic interference (EMI), protecting sensitive internal electronics from external noise while allowing visual access.

- Anti-Static Properties: It provides a path for static charges to dissipate, preventing damage to sensitive components and reducing dust attraction.

- Heating Capabilities: By passing current through the ITO layer, it can generate gentle heat, ideal for anti-fogging or de-icing transparent plastic surfaces.

Practical Applications of Electrically Conductive Plastic

The integration of plastic and electricity is already transforming numerous industries:

- Touchscreens: Flexible ITO-coated plastic films are at the heart of modern touchscreens in smartphones, tablets, and interactive kiosks, especially those designed to be flexible or shatter-resistant.

- Flexible Displays: Enabling the development of next-generation bendable, rollable, and foldable displays for consumer electronics and signage.

- Wearable Technology: Smart garments, health monitoring patches, and other wearables benefit from plastic’s comfort and flexibility combined with electrical functionality.

- Transparent EMI Shields: Used as clear windows in sensitive electronic enclosures (e.g., medical devices, aerospace) to block interference without obstructing views.

- Heated Plastic Windows: Preventing fogging or icing in specialist vehicle visors, freezer display cabinets, or other transparent plastic components.

At ITO Plastic, we’re dedicated to pushing the boundaries of what plastic can do. By applying our advanced ITO coatings, we’re helping clients create innovative products that leverage the best of both worlds: the versatility of plastic and the power of electricity.

If your next project demands a material that offers conductivity without sacrificing clarity or flexibility, our experts are ready to assist.